📣 BAST Machine at the Bursa Machine Fair!

📅 Date: November 28 – December 1, 2024

📍 Location: Tüyap Bursa International Fair and Congress Center

🏢 Hall: 4

🎯 Stand: 417

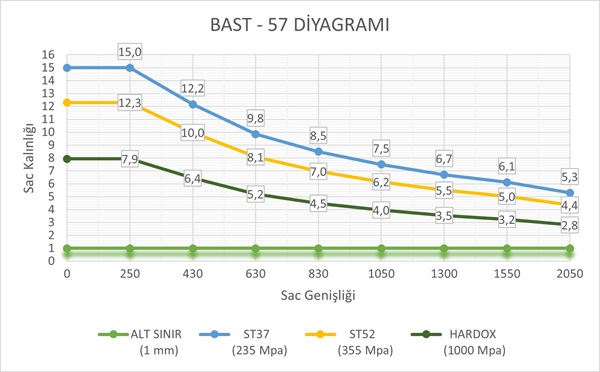

As Meşe Makina, we are showcasing the most innovative sheet metal processing solutions at the Bursa Machine Fair! Our advanced model, the BAST 57-1550 sheet leveling machine, along with the 5-ton Tool Mover Machine, will be on display. Visit us to learn more about our new technologies and get a closer look at our products.

👥 Come and let’s discuss the future of machine technology together!

📞 Contact: +90 224 241 24 01

✉ Email: info@mesemakina.com

Introduction Videos

Bast Machine Introduction Film

Bast Machine Introduction Film

Yepsan Group

Enhances Precision with BAST Machine

Istanbul Perforated Sheet Metal

Opinions about Bast

Bast® SHEET LEVELING MACHINE

Features

Nowadays, roller leveling technologies are rapidly replacing the old methods in laser sheet metal cutting, flame cutting or in the elimination of defects in perforated sheets. The roller leveling machine reduces the internal tension of the sheet metal parts coming from laser cutting and straightens them. In this way, the process quality is increased in production processes such as precision welding, bending and twisting following leveling and a positive contribution is made to all production processes.

Compared to other leveling processes, roller sheet leveling is fast, economical, short, simple and can be performed with a short training for technical personnel. Leveling rollers that can be used in both directions minimise wear while extending the service life of the roller. Thanks to the fast cleanable mould structure, the cassettes can be removed on the motorised stand and cleaned easily.

By equipping the BAST® Machine with an overload protection system, the fatigue strength and service life of the machine are increased. BAST® Machine mould cavity settings are supported by sensitive sensors to ensure that the leveling precision process remains stable. Thanks to the EASYBAST touch screen, machine settings can be made in precise value ranges and the programme can be used easily.

Bast® SHEET LEVELING MACHINE

EASYBAST Touch Screen

Thanks to the EASYBAST touch screen, machine settings can be made in precise value ranges and the programme can be used easily.

BAST® SHEET LEVELING MACHINE

Fine Tuning

The BAST® machine is equipped with sensitive sensors for mould cavity adjustment. It is ensured that the flattening precision process remains stable.

Bi-directional leveling rollers minimise wear while extending the life of the roller. Thanks to the quick-clean mould structure, the cassettes can be removed and cleaned easily on the motorised stand.

Gallery

Bast® SHEET LEVELING MACHINE

Technical Data

BAST® SHEET LEVELING MACHINE

Bast® In The Media

Sheet Metal Leveling Machine Produced With Domestic Facilities Was Introduced.

As of 2022, despite some negativities, progress has been made in machinery manufacturing and exports in the world and Turkey. 100 per cent domestic machines attract great interest in Turkey and in fairs around the world.

Locally produced sheet metal leveling machine introduced – Breaking News | NTV News

Machinery manufacturing and exports 2022 developments and 2023 forecasts shared – Tele1

Machinery Manufacturing And Export Sector Affected By The Pandemic Is On The Rise Again

Meşe Makina Founder Mehmet Selim Akkök evaluated the latest situation in the sector. Within the framework of expectations, machinery and equipment investments are expected to stagnate in the first half of 2023 and enter a growth process again in the second half.

BAST® SHEET LEVELING MACHINE

Call Us Now

Call us

CONTACT INFORMATION